Industrial Compressor Predictive Maintenance

Why Compressor Maintenance Needs a Rethink

Industrial compressors are critical assets in manufacturing, energy, pharmaceuticals, and other industries. However, traditional maintenance approaches—reactive and preventive—are increasingly insufficient. Reactive maintenance results in costly downtime and safety hazards, while preventive maintenance often wastes resources. With the rising cost of energy, stricter compliance requirements, and tighter production deadlines, predictive maintenance provides a smarter, more efficient solution.

Understanding Predictive Maintenance

Leveraging IoT sensors, machine learning, and real-time monitoring, Predictive maintenance (PdM) predicts failures before they occur. By analyzing parameters like vibration, temperature, and pressure, PdM systems send alerts when performance anomalies are detected. This ensures maintenance is performed only when necessary, optimizing costs and reliability.

Why Predictive Maintenance is the Future of Industrial Compressors

The Challenge of Compressor Maintenance

Compressors are the lifeline of process and manufacturing industries—pharma and petrochemicals, food and beverages. Compressors reduce air tools, cooling systems offline, and whole assembly lines shut down.

To plant engineers and maintenance managers, of most concern is that they operate those compressors. But conventional maintenance never offsets cost and reliability with effectiveness.

- Reactive maintenance swamps the workplace with clutter when equipment fails at most inconvenient time.

- Preventive maintenance, although routine, can lead to labor wastage and unnecessary replacement of parts.

Both the approaches are not possible in the current age of competition, energy efficiency, and end-of-life protection. Predictive maintenance (PdM) comes to the rescue—a brilliant approach that leverages IoT, machine learning, and real-time monitoring to optimize industrial compressors’ performance.

The Failings of Reactive and Preventive Maintenance

Postponing Failures: Reactive Maintenance

In Reactive maintenance, businesses repair compressors when they fail. Although it appears to be economizing on the initial process, in the long run, it will end up spending a large amount of money.

Drawbacks of Reactive Maintenance:

- Unplanned downtime: Even halted few hours of production may result in tremendous financial losses, delayed delivery schedules, and dissatisfied customers.

- Costly repair bills: Stopgap measures will always cost more than expected interventions.

- Safety risk: Compressors are pressure vessels; failure creates unsafe operating conditions.

Preventive Maintenance: On Time, Not Always Successful

A more proactive approach, Preventive maintenance fixes checkups and spares at a particular point in time. While superior to doing nothing, not always successful.

Weak areas are:

- Too much maintenance: Replacement of parts ahead of time is dollar- and man-hour-wasting practice.

- Missed notice: Issues that occur between inspection periods are overlooked.

- Brush-over approach: Prevention schedules do not adapt to real equipment condition and operating conditions.

Reactive maintenance is too late, and preventive maintenance is too early. Predictive maintenance employs the accuracy balance industry has sought.

What Is Predictive Maintenance for Industrial Compressors?

A data-driven methodology, Predictive maintenance (PdM) monitors compressor condition in real time and predicts failures before they occur. Not schedules or estimates, PdM uses advanced tools to monitor for performance trends around the clock and detect subtle warning signs.

This is the overall process:

- IoT Sensors capture accurate parameters like vibration, pressure, oil condition, temperature, and power intake.

- Data Streaming provides 24/7 visibility to equipment condition, usually in the form of cloud-based dashboards.

- Machine Learning & AI Analytics detect abnormal patterns, potentially signals of wear, imbalance, or inefficiency.

- Predictive Alerts alert maintenance staff, enabling them to repair at best cost-savings opportunity.

The result? Compressors are practically self-reporting assets, reporting in real-time on condition and performance.

Benefits of Predictive Maintenance for Industrial Compressors

The worth of predictive maintenance goes an absolute, absolute distance further than keeping dollars saved—it actually reshapes the manner in which factories maintain their most expensive assets in working order.

-

Decreased Downtime

- Plan breakdowns ahead of time and fix them in planned downtime.

- Minimize production bottlenecks due to surprise haltages.

-

Cost Savings

- Minimize the expense of last-minute emergency action.

- Prevent unnecessary replacement of good components.

- Decreased total maintenance cost with efficient labor scheduling.

-

Increased Equipment Life

- Maintain premature wear before damage becomes large-scale.

- Compressors remain within a safe operating envelope, not blowing motors, bearings, and valves.

-

Increased Efficiency

- Compressors operate at optimal efficiency.

- Less energy used—a fundamental advantage due to the ever-rising cost of electricity across the world.

-

Next-Generation Safety & Compliance

- Monitor malfunctions that hurt employees.

- Provide regulatory compliance in food processing, oil & gas, and pharma industries.

-

Data-Driven Decisions

- Invest cash with future expectations judiciously.

- Design performance reports including all of the data to enable audits, budgeting, and review by management.

Why Predictive Maintenance is the Future of Compressor Reliability

Industry 4.0—analytics, automation, and connectivity are the key to success in operations globally. Predictive maintenance is the organic connector of this digital era.

- Industrial IoT adoption is gaining speed, reducing the cost and scalability of sensors.

- Cloud and AI have even made real-time analytics a possibility for mid-sized companies.

- Competitive pressures make inefficiency and downtime unacceptable.

In this kind of culture, Predictive maintenance is no longer something to debate—now it’s something everybody expects from compressor reliability. Those who are early to adopt predictive maintenance will have a clear edge when it comes to profitability, safety, and productivity.

How to Roll Out Predictive Maintenance in Your Business

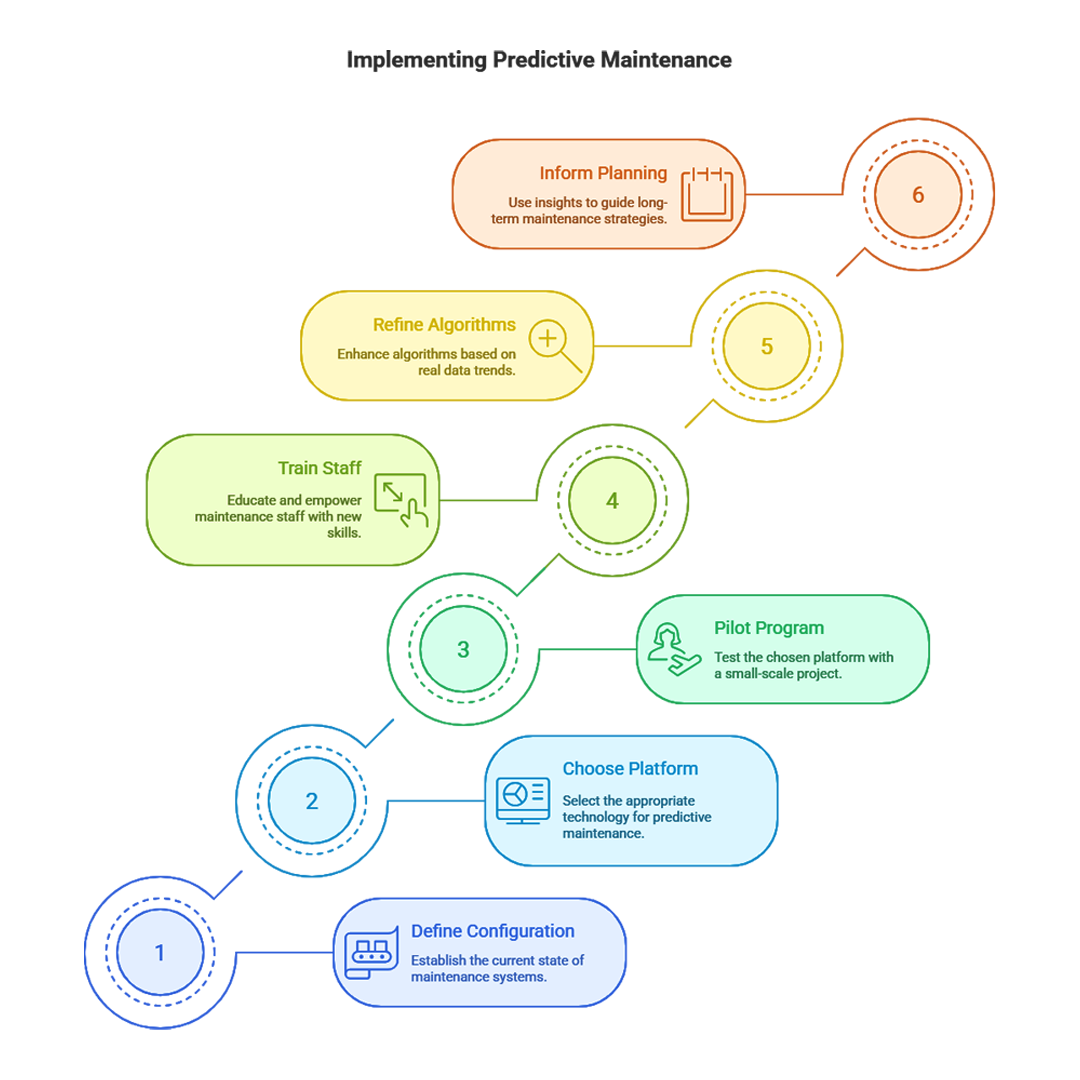

You do not have to swap the whole system in order to be predictive. Incremental deployment makes it easy for firms to deploy the technology.

Step 1: Define Your Current Configuration

- Pinpoint mission-critical compressors.

- Map existing sensor configurations and overlay retrofitting requirements.

Step 2: Choose the Proper Predictive Maintenance Platform

- Utilize platforms that deploy simply into your existing IoT infrastructure.

- Find cloud dashboards, predictive code, and vendor incentives.

Step 3: Pilot-Proof with a Pilot Program

- Implement predictive maintenance on a pilot scale—i.e., one or two of your essential compressors.

- Monitor increases in downtime, cost savings, and energy conservation—the pillars of sound predictive maintenance.

- Scale up after ROI is firmly established.

Step 4: Train and Empower Your Maintenance Staff

- Train staff to read predictive intelligence confidently and act on it.

- Create an anticipatory culture where the technicians anticipate prior to failure instead of reacting after.

- Optimize Continuously

Step 5: Improve algorithms and fine-tune strategies from genuine trends of data.

Step 6: Use insights to inform long-term maintenance cost and capital planning.

Conclusion: Future-Proofing Industrial Operations

Industrial compressors are too important to bet on traditional practices of maintenance. Predictive maintenance using IoT, AI, and data analysis brings in the reliability, efficiency, and cost savings that contemporary industries need.

To factory owners, plant managers, and reliability engineers, predictive maintenance isn’t an upgrade in technology – it’s future-proofing the company. It repays in safety, sustainability, and profitability, and it’s one of the wisest investments industrial companies can make today.

The cat is out of the bag: it’s time to move away from reactive and preventive calendars and into predictive maintenance.

Your suggestions & insights are most welcome. Please leave a comment below.