Why OEM-grade Compressor Spares?

Why K‑Nine Spares Recommends OEM‑grade Compressor Spares Every Time

At K‑Nine Spares, plant managers ask us one question daily: “Are OEM‑grade compressor spares really worth the price?” The answer is simple: Yes — if uptime matters, then OEM‑grade compressor spares are worth every penny.

Here’s why it matters more than price alone.

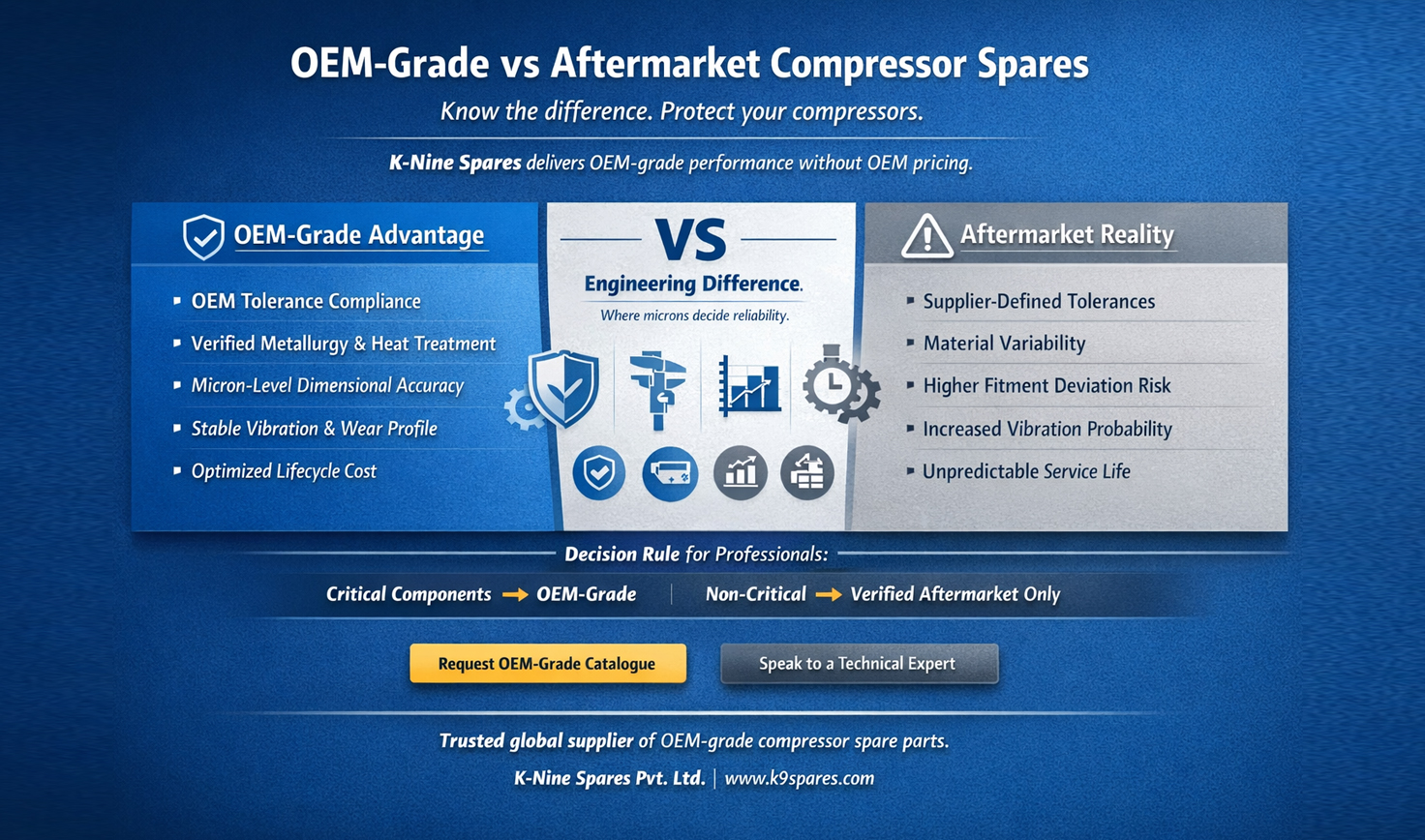

OEM‑grade compressor spares vs. Aftermarket: Definitions That Matter

OEM-grade spares are built to exact OEM tolerances and material specs. They match original performance expectations. Aftermarket spares are made to supplier-defined standards.

This difference drives performance, reliability, and cost. It separates confident operations from risky guessing.

The Reliability Edge of OEM-Grade Spares

Studies show OEM-grade components retain ~97% efficiency after 5,000 operating hours. Aftermarket alternatives drop to ~82% in the same period.

Stable efficiency means more uptime, less waste, and higher profit. OEM‑grade is not about brand — it’s about predictable performance.

Material Quality and Engineered Precision

OEM-grade parts use controlled metallurgy, precise heat treatment, and CNC machining. Aftermarket materials can vary widely.

Compressors operate under high stress and heat. Inferior alloys accelerate wear. Small differences today create failures tomorrow.

Dimensional Accuracy Isn’t Optional

Compressors depend on micron-level tolerances. OEM-grade parts match original dimensions precisely. Aftermarket parts often allow wider deviations.

Poor tolerances cause vibration, energy loss, and early breakdowns. Precision isn’t luxury — it’s reliability.

Performance That Shows Up in Numbers

OEM-grade spares maintain stable efficiency and low vibration. Aftermarket parts often produce irregular wear and a higher failure probability.

Vibration stresses bearings, seals, and shafts. It shortens life and increases maintenance costs. A 30% performance difference is downtime and lost revenue.

Cost vs Lifecycle Savings: Smart ROI

OEM-grade components cost 20–35% more upfront. Aftermarket parts are cheaper initially. But aftermarket failure rates can be ~18% higher in the first year.

Replacement frequency rises. Downtime increases. Lifecycle cost, not purchase price, drives real ROI.

Warranty and Risk Considerations

OEM-grade spares carry stronger warranty coverage and support. Aftermarket coverage is often limited.

Void warranties cost more than parts — they cost liability, trust, and uptime. OEM‑grade protects both performance and warranty compliance.

Where Aftermarket Parts Work

Not all aftermarket parts are bad. For non-critical consumables, such as filters, gaskets, or seals, quality aftermarket parts are effective. However, core compressor components — such as pistons, bearings, valves, crankshafts, connecting rods and oil pumps — require OEM-grade compressor spares.

Here, uptime and reliability outweigh short-term savings.

K‑Nine Spares Decision Rule

Our rule is simple:

Critical components → OEM‑Grade

Non-critical components → Verified aftermarket

No guessing. No “maybe it works.” Just decisions that safeguard uptime and reduce risk.

Real Industry Outcomes

Across 47 industrial plants, OEM-grade compressor spares ran ~12% more efficiently than aftermarket systems. A 12% efficiency gain may seem small. Until you measure energy, maintenance hours, and lost production.

Then it directly impacts your bottom line.

Final Bottom Line

Saving on parts today often costs more tomorrow. OEM‑grade Compressor Spares protect uptime, reduce risk, and lower lifecycle costs. It preserves design intent, reliability, and warranty coverage. At K‑Nine Spares, we don’t just sell spares. We protect operations, optimize cost, and ensure uptime.

For critical compressor systems, OEM‑grade Compressor Spares is the smarter choice.

Ready to Make the Smart Choice?

Connect with K‑Nine Spares. We’ll match the right OEM‑grade spares to your compressors. Because the right choice today prevents costly failures tomorrow.