Top 5 Compressor Maintenance Mistakes & How to Prevent Them

Introduction: Why Compressors Fail Early

All compressor owners fear the day operations grind to a halt. Imagine a senior plant manager, with horror in his eyes, as tens of thousands of dollars’ worth of losses mount up—all due to avoidable compressor maintenance mistakes.

Industry data indicate that more than 90% of compressor failures are not by accident—it’s human error. When compressors “run out of steam,” it’s often due to neglect, not destiny.

Today, in this blog, we will try to uncover the five most dangerous compressor maintenance mistakes, putting your uptime, profit, and reputation at risk.

Each is backed by real stats, real impact, and real-world solutions so that you never become a cautionary tale in the evolving compressor spare parts industry.

Reliable Compressor Spare Parts make a world of difference.

The Industry Snapshot: Why Proper Maintenance Matters

The compressor spare parts business is growing. It is estimated to grow up to $29.94 billion by 2029.

Compressed air shall power 39.1% of activities in 2025 alone. But like all revolutions, there comes a new era of errors, most since old practices attempt to accommodate today’s sophisticated systems.

Compressor downtime is not only inconvenient—it can undermine entire supply chains and cost companies tens of thousands of dollars per incident.

The future belongs to those who become proactive, data-driven, and relentless about compressor maintenance.

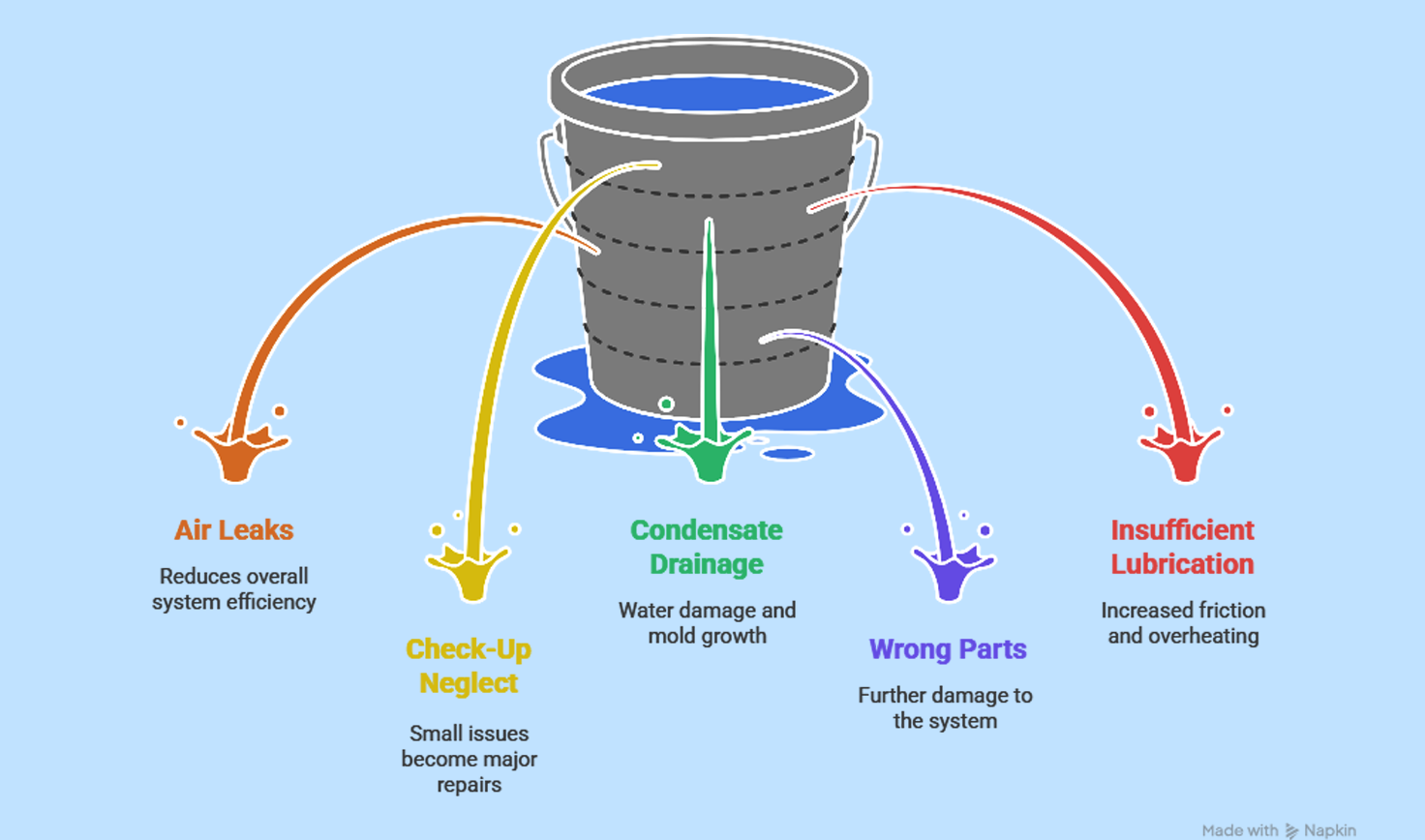

Mistake #1: Ignoring Air Leaks (The Silent Profit Drain)

Little devils that leak. Left unchecked, they’ll blow off up to 50% of your compressed air. That’s half your energy bill, possibly blowing straight out into thin air.

The haemorrhage of cost is enormous. Energy wastage due to air leaks can be more than the cost of the compressor, at times, even in the first year. In a large plant, air leaks can cost $2,500–$8,000 per year for each compressor.

How to Avoid It:

- Regular leak checking, such as ultrasound or old-fashioned soapy water, is recommended, especially on and around valves, fittings, and hoses.

- Don’t underestimate the impact—busting a small leak can save thousands annually.

Mistake #2: Forgetting Regular Check-Ups (Out of Sight, Out of Mind)

Avoid inspections, and you might as well leave the doors open to breakdowns. Forgotten inspections result in ignored warning signs—vibrations, odd noises, oil leakage, that grow into catastrophic breakdowns.

Research indicates that regularly scheduled checks can detect problems weeks before they turn into costly nightmares. A well-maintained air compressor lasts years longer than its neglected counterpart. Without regular checks, you’re taking your uptime for a gamble.

How to Avoid It:

Establish an uncompromising inspection schedule. Listen, observe, and record facts monthly—especially on moving parts and electrics. Train staff to identify red flags early. Documentation is your lifeblood.

Mistake #3: Failure to Drain Condensate (Water, Rust, and Destruction)

Think water is harmless? Think again. In moist conditions, undrained condensate will accumulate in the tanks, causing corrosion, rust, and blocked lines. It will ruin the compressor as well as the final product in the long term.

Operators overlook or forget this obligation and convert virgin machines into detonation-ready time bombs. In extreme cases, tanks have blown up as water accumulated in them, endangering lives and million-dollar machinery.

How to Avoid It:

Install auto-drains or make manual drainage an everyday task. Especially in moist environments, mandatory condensate drainage needs to be enforced. Remember: Water is nature’s best saboteur.

Mistake #4: Fitting the Wrong or Obsolete Spare Parts (Shortcuts to Downtime)

The urge to take shortcuts with cheaper, non-OEM-grade/quality spare parts is tempting even for seasoned managers. Substandard parts, however, will shut down compressor operations, invalidate warranties, and encourage premature failures.

According to expert estimates, low-quality spare parts shorten compressor life by as much as 30%. Most high-profile failures have originated from counterfeit seals, under-spec filters, or sub-standard valves.

How to Avoid It:

Purchase exclusively from high-quality suppliers who provide authenticity guarantees. Leaders such as K9Spares offer OEM-grade compressor spare parts, equal to or superior in quality to the original.

Real-time quality information, stringent testing, and committed support safeguard your investment and peace of mind.

Mistake #5: Insufficient Lubrication (Friction Kills Quick)

Compressors thrive on precision lubrication. Using the wrong oil—or worse, running dry—can grind gears, overheat rotors, and turn a robust machine into expensive scrap.

Up to 40% of catastrophic compressor failures are caused by lubrication issues. The cost? Complete surprise shutdowns, ruined bearings, and a repair bill that’ll make your money managers howl.

How to Avoid It:

Follow your owner’s manual guidelines on oil type and replacement periods. Check levels weekly, change filters regularly, and record each oil change. Uncertain? If required, speak with your supplier more than necessary—the life of your compressor depends on it.

The Emotional Toll: Real-World Pain & Redemption

Say hello to Priya, a production manager at a medium-sized plant. Her plant had a crippling compressor failure last summer due to routine air leaks and missed inspections. The outcome? Four days lost, $60,000 production loss, and sleepless nights.

After that expensive lesson, she redesigned her maintenance habits, spending more on higher-quality spare parts and computerized leak detection.

One year later: no unexpected shutdowns, 18% productivity gain, 30% reduction in maintenance expense.

Stories like Priya’s demonstrate: Knowledge isn’t just power—it’s profit, reputation, and peace of mind.

The Forward-Thinking Solution: Data, Tech, and Culture

The intelligent, data-based compressor maintenance future. Real-time IoT sensors monitor vibration, temperature, and pressure, alerting teams before a disaster.

Weeks in advance, predictive analytics detect risks, meaning scheduled, not surprised, downtime.

Manufacturers who fit the latest variable speed drive (VSD) compressors are already reducing energy expenditure by as much as 60%. When your level of maintenance sophistication matches your machine’s intelligence, breakdowns are a thing of the past.

K9Spares: The Established Industry Leader in Compressor Spares

When you need parts that you can trust, K9Spares provides OEM-grade compressor spare parts compatible with leading brands around the globe. Their spares pass stringent demands, experiencing thorough endurance testing under real-life conditions before reaching your workshop. With advanced CNC production, live quality inspection, and experienced personnel, K9Spares ensures your compressors operate flawlessly.

Selecting K9Spares isn’t only intelligent—it’s an investment in compliance, safety, and long-term success for your operation. In a world of cutting corners, they’re the industry gold standard for reliability.

The Numbers Don’t Lie: Why It Pays to Get Maintenance Right

- More than 90% of compressor failures can be avoided.

- Leaks in the air system can result in up to 50% of compressed air being wasted, costing thousands annually.

- Replacement parts that are not OEM-grade can shorten compressor life by 30%.

- Regular maintenance and active inspection lower downtime by as much as 40%.

Each statistic, each anecdote, bears witness to one fact: There’s no honor in unnecessary failure. There is, however, aplenty in operational excellence.

Conclusion: Your Compressor Success Checklist

Be the hero, not the statistic. Your route to compressor reliability is straightforward:

- Hunt down and fix every air leak.

- Inspect, record, and act—constantly.

- Drain all condensate, every time.

- Demand genuine, quality spare parts.

- Love your lubricants—your compressor will love you back.

Let data inform you, let technology enable you, and let distributors such as K9Spares place you ahead of the curve. In today’s hectic, ever-changing world of compressor spares, individuals who steer clear of these errors don’t simply exist—they thrive.

Here is a clear and practical Daily Compressor Maintenance Checklist based on industry best practices and expert sources:

- Inspect for oil leaks, loose bolts, and vibrations.

- Check oil level and top up if required.

- Drain condensate/water from the receiver tank.

- Check pressure and temperature gauges for normal readings.

- Monitor the compressor for unusual noises or irregular operation.

- Clean the air intake filter and housing if visibly dirty.

- Check safety valves and pressure relief valves for proper function.

- Tighten any loose bolts or nuts on the compressor housing and baseplate.

- Record all readings, observations, and maintenance in a logbook.

These tasks ensure early detection of problems such as leaks, lubrication issues, and condensate build-up—key causes of compressor failure. Regular daily checks help prevent costly downtime and extend compressor life.

This checklist is suitable for most industrial compressors and can be adjusted slightly depending on your specific compressor model and environment.

If you have any more suggestions, insights – please leave a comment below. Your thoughts are more than welcome!